In modern manufacturing, unexpected equipment failure represents one of the largest threats to productivity and profitability. The traditional approaches of waiting for a breakdown to occur, known as reactive maintenance, or performing maintenance based on fixed schedules, known as preventive maintenance, are no longer sufficient to meet the demands of lean operations. Today, the focus has shifted to Predictive Maintenance (PdM), a sophisticated, data-driven strategy that anticipates failures, allowing intervention just before a critical issue arises.

The core ingredient for this transformation is the seamless integration of Industrial Internet of Things (IIoT) technology with enterprise systems, a connection made possible by powerful integration solutions like Aonflow. This bridges the historical gap between the shop floor’s Operational Technology (OT) and the back office’s Information Technology (IT), creating a truly intelligent factory ecosystem ready for the future of smart manufacturing.

The Sensor-to-Data Pipeline and Edge Processing

Predictive maintenance begins with continuous, granular data collection from the equipment itself. IIoT sensors, installed on critical assets like motors, gearboxes, and robotics, measure vital signs in real-time. This includes monitoring minute changes in vibration signatures, which are often the earliest indicators of bearing wear, component misalignment, or imbalance. Similarly, sensors track temperature, as elevated or inconsistent heat can signal overheating, friction, or electrical stress. Advanced systems also monitor acoustics to pinpoint minor mechanical faults through unusual noises, and track current and voltage fluctuations that reveal mechanical strain or impending electrical failure.

To handle this massive volume of raw OT data at high velocity, many modern deployments rely on Edge Computing. This involves processing and filtering data directly at the machine level, reducing the volume of data sent to the cloud or central server. This near real-time processing capability is crucial, as a sudden spike in a vibration reading needs immediate analysis to prevent catastrophic failure. The Edge filters out normal operating noise and sends only the relevant anomalies—the “signal”—to the next stage.

The Analysis Engine: Machine Learning and Predictive Models

Once the clean, high-value data leaves the edge, it is fed into an Advanced Analytics platform that houses Machine Learning (ML) models. These models are the heart of PdM. They do not just flag when a measurement exceeds a fixed threshold; they compare the incoming real-time data against years of historical operating data, maintenance logs, and even environmental variables.

The ML models are trained to recognize complex, multivariate patterns that precede a failure—patterns often invisible to human inspection or simple alert rules. The output of this stage is not just an alarm, but a Failure Probability Score and a Time-to-Failure estimate. This predictive insight is what differentiates PdM from traditional condition-based monitoring.

Aonflow: Orchestrating the Predictive Response

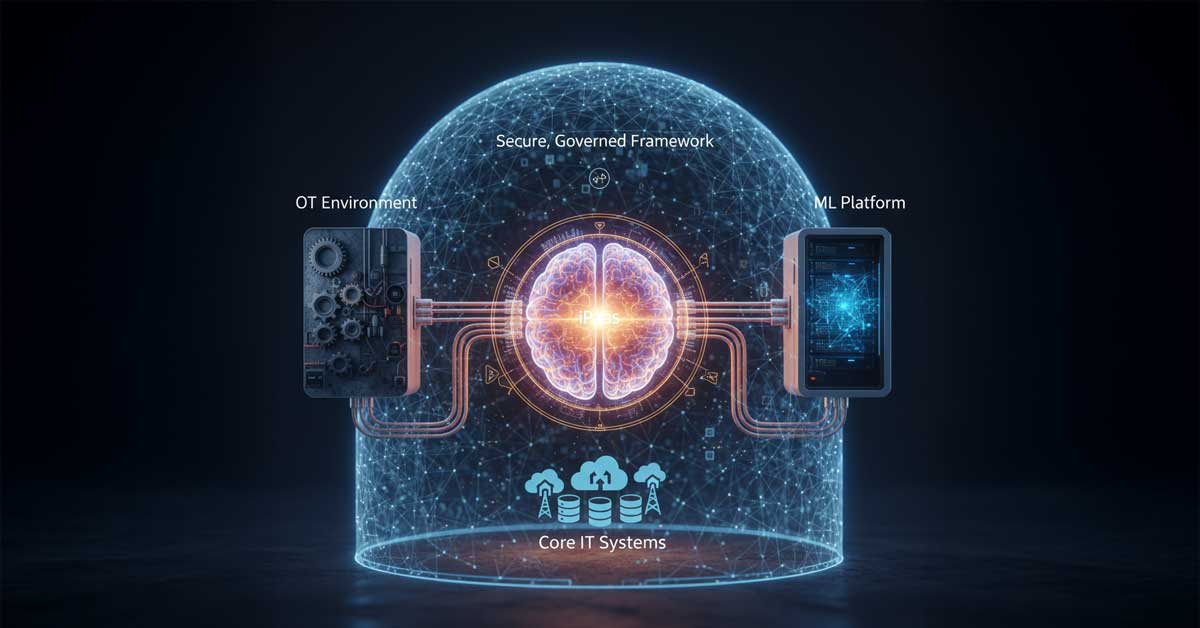

Aonflow, as an Integration Platform as a Service (iPaaS), serves as the central nervous system that makes this Predictive Maintenance workflow possible at an enterprise scale. It provides the secure, governed framework necessary to connect the complex OT environment, the ML platform, and the core IT systems.

The Aonflow platform is responsible for several critical steps:

- Secure OT/IT Connectivity: Aonflow provides resilient, pre-built connectors and an architectural framework to securely connect to diverse data endpoints, from cloud-based Machine Learning platforms to on-premises enterprise systems like the CMMS or ERP.

- Data Harmonization and Contextualization: Aonflow takes the analytical output (e.g., an 85% failure probability) and transforms it. It translates this data by linking it to crucial business context—the specific Asset ID from the CMMS, the location, the required Spare Part Number from the ERP system, and the current Production Schedule.

- Workflow Automation: Aonflow manages the immediate, automated cross-system response to the insight using its low-code interface. This workflow is critical for efficiency:

- IF the ML prediction indicates high risk, Aonflow automatically creates a high-priority Work Order in the CMMS.

- It then queries the ERP system to check and reserve the necessary part.

- Finally, it notifies the relevant maintenance technician via their mobile device.

This coordinated, end-to-end response ensures that an early warning signal from the factory floor triggers a seamless business action across the entire organization. For example, one large-scale manufacturer used Aonflow to reduce their average unplanned outage time by 40% after implementing this fully automated workflow.

The Business Case for Integration

The successful integration of IIoT, ML, and enterprise systems results in concrete, measurable benefits that directly impact the bottom line. Manufacturers gain a competitive edge by achieving better operational metrics:

- Reduction in Unplanned Downtime: Eliminating the costly surprise of major production stoppages.

- Optimized Resource Use: Scheduling maintenance precisely when it is needed, conserving labor and material costs.

- Extended Asset Lifespan: Correcting minor issues early on, preventing small faults from escalating into catastrophic failures.

- Improved Safety: Reducing the risk of serious workplace accidents caused by sudden mechanical failure.

Ultimately, the fusion of IIoT data and IT orchestration, powered by Aonflow, delivers a more efficient, cost-effective, and safe production environment, driving higher Overall Equipment Effectiveness (OEE) across the entire factory. The predictive factory is not just a dream of efficiency; it is a reality driven by intelligent data integration.